I’ve been meaning to make a beaded wire bangle for ages – you know that lovely silver wire that looks like lots of silver beads – I finally had chance and I though it looked great.

BUT…It felt a little flimsy.

In my rush to get creative I had ordered 2mm beaded wire – 2mm round is fine for bangles – but of course 2mm beaded wire is thinner between the beads.

I tumbled the bangle for 2 days, hammered like mad with a nylon mallet and still it wasn’t hard enough, i even tried hammering with a metal hammer, the bangle looked even better but still too soft.

I am just a little obsessive and can’t let go but finally I had an idea that I thought would work…..

Serendipity – Lucky Mistake !

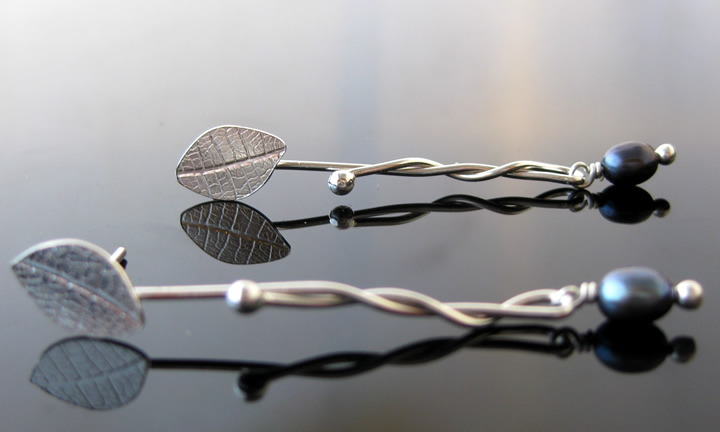

So here they are, 2 pairs of Serendipity Earrings, one pair all shiny and even, the other matt and more hammered/bigger balls in the middle – They are for sale (just cick on the images) but be quick, I might get the next bangle right 🙂

How – I cut the bangle into 4, evened up the lengths so I had 2 pairs, sanded the ends smooth and hammered one pair in the middle so the bubbles are larger then get smaller. All I had to do then was solder the stud pin on the back and check that the silver was still hard and hadn’t annealed. Voila (as they say constantly here) fabulous, long studs – they do look great on.

Coming to my website soon – Serendipity Bangle – A thicker version that will work !